To provide a simple sustainable technology with minimum operational cost to the underprivileged who have limited access to water and electricity and to people who care about the environment.

Through education and technology we endeavor to teach industry, analytical thinking and ingenuity, which could be considered building blocks upon which they could become self-sufficient to the point of creating revenues, which could then be used to reach out to other communities in need.

To create a grassroots level organization that in due time could operate independent of outside support. We would want to see this organization utilizing technology fueled by natural energy from the sun, wind and water.

In 1999 we wanted to supply water to a children's home, located high up in the mountains of Northern Thailand. Initially, we deployed a conventional gasoline-powered water pump, which, quite predictably, proved to be by far too costly, both in running and maintenance terms.

We subsequently discovered the ram pump concept and purchased a number of commercially available units, some of which failed miserably to deliver water to our site 20 meters above and 800 meters away from a fresh-water stream. Hence, we decided to develop our own pump from standard fittings, including all kinds of check valves, in combination with various types of metal, PVC, PE & PU fittings, etc.

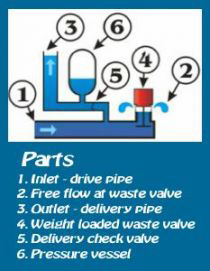

A hydraulic ram pump has only two moving parts:A mostly weight loaded waste valve, sometimes known as the clack valve and a delivery check valve, which makes the pump operation reliable and easy to maintain.

Other non-moving parts are the drive pipe which supplying water from an elevated source and a delivery pipe, taking a portion of the water that comes through the drive pipe to an elevation higher than the original water source.

At the beginning of the cycle, the waste valve (4) is open and the delivery valve (5) is closed. The water in the drive pipe (1) starts to flow by gravitational force, picks up speed and kinetic energy until it forces the waste valve to shut close.

The momentum of the water flow in the drive pipe (1) against the presently closed waste valve (4) creates a so-called water hammer, which raises the pressure inside the drive pipe (1) and the pump body and thus opens the delivery check valve (5).

This allows a portion of the water under pressure to escape into the pressure vessel (6) and the delivery pipe (3). Since this water is being forced through the delivery pipe (3) against gravity, its flow slows down and finally reverses, closing the delivery check valve (5) closes. If all water flow has stopped, the pressure inside the drive pipe (1) equals ambient pressure, which makes the waste valve (4) reopen to allow the above cycle to start again.